Aug, 2021 - By WMR

Researchers at the University of Minnesota Twin Cities College of Science and Engineering developed a technology that can make a strong group of metals and metal oxides.

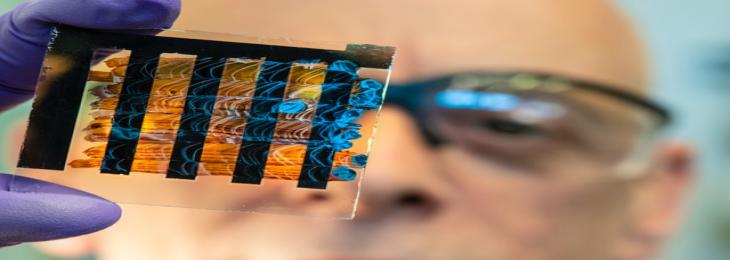

Most metals are made into thin films to use in technological products such as displays, electronics, fuel cells, operating equipment, and others. The hard metals including materials such as iridium, platinum, ruthenium, tungsten, and others are very difficult to convert into thin films as they require extreme temperatures usually 2,000 degrees Celsius to explode. Usually, scientists assemble these metal films using techniques such as the evaporation of an electron beam. The proceeding methods consists of melting and condensing metal at high temperatures which leads to formation of thin films.

However, this standard method is hefty, uses a lot of energy, and may not be safe due to the high power consumption. Hence, researchers at the University of Minnesota developed a method of evaporating these metals at very low temperatures, below 200 degrees Celsius instead of a few thousand. By building and adding organic ligands, a mixture of hydrogen, carbon, and oxygen atoms to metals, researchers being able to significantly increase the vapor pressure of matter, making it easier to rise to lower temperatures. The new process is not only simple but also makes high-quality items that are easily dispersed. There is already a historical link between the innovation in synthetic science and the development of new technologies.

Millions of dollars go into building materials for various applications. Fortunately, the sector has come up with a technology that offers better atomic precisions. These metals are used to make many products, from semiconductors to computer systems display technology. Platinum, for example, also makes a significant incentive for power conversion and energy conservation and is considered for use on spintronic devices. Reducing the cost and complexity of metal installation while allowing for the installation of complex substances such as oxides will play a major role in industrial developments in near future.

We will be happy to help you find what you need. Please call us or write to us: